Key Components of the Graph:

1. Axes:

- X-Axis (Distance): Represents the distance over which electricity is transmitted.

- Y-Axis (Cost): Represents the cost of transmission systems.

2. Cost Lines:

- HVAC Cost Line: This line typically shows a steeper slope, indicating that the cost of HVAC systems increases significantly with distance. HVAC systems are generally more expensive to maintain over long distances due to higher energy losses.

- HVDC Cost Line: This line has a gentler slope, indicating relatively lower costs over long distances. HVDC systems become more cost-effective as the distance increases, primarily due to reduced transmission losses and lower infrastructure costs over long spans.

3. Economic Crossover Point:

- The point where the two lines intersect is referred to as the "economic crossover." This point indicates the distance at which HVDC systems become more economical compared to HVAC systems. Beyond this distance, HVDC is typically the preferred choice for transmission.

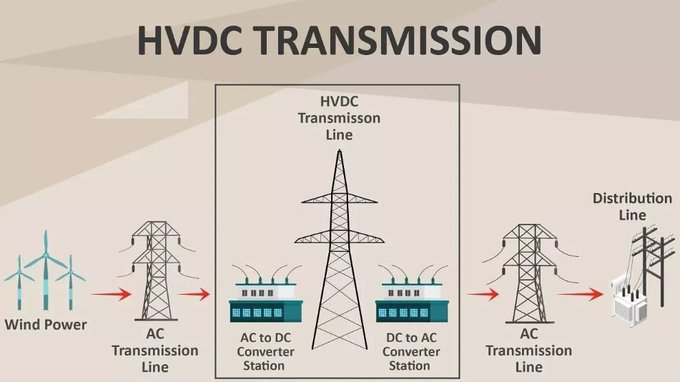

Overview of Concepts:

The graph illustrates the economic viability of HVAC and HVDC transmission systems based on distance. In general:

- HVAC Systems: Suitable for short to medium distances, with significant energy losses over longer distances. Their costs increase rapidly as the transmission distance grows.

- HVDC Systems: More efficient for long-distance transmission due to lower energy losses and reduced infrastructure requirements. They become the more economical choice as the distance increases, making them ideal for connecting remote renewable energy sources to the grid.

Overall, this analysis highlights the importance of choosing the appropriate transmission technology based on distance, which is crucial for optimizing costs and improving the efficiency of power delivery.