Welcome to SparkED, your ultimate destination for all things engineering, science, and innovation! Our blog is a vibrant platform dedicated to showcasing the latest advancements, groundbreaking research, and fascinating discoveries in the world of electrical engineering and beyond. At SparkED, we believe in the power of knowledge and its ability to ignite extraordinary ideas. Our team of passionate writers and researchers is committed to bringing you captivating articles.

Tuesday, 8 August 2023

Three reasons why wind energy is better than coal

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

Aluminum for overhead lines

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

Monday, 7 August 2023

Oil circuit breaker OCB

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

Unsymmetrical faults

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

Wednesday, 26 July 2023

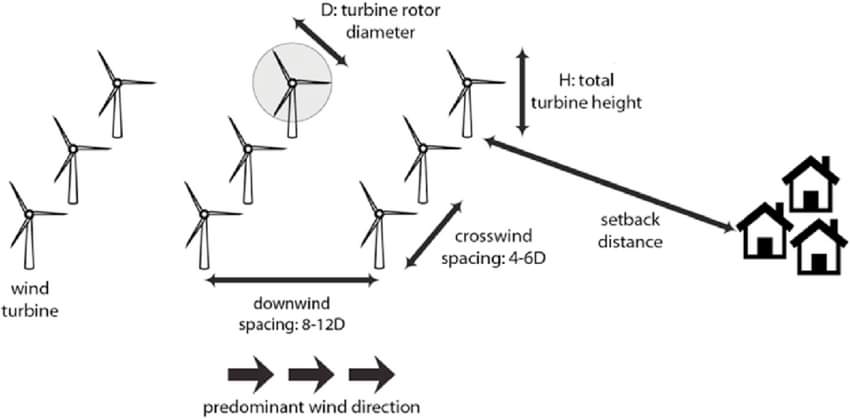

Spacing between wind turbines

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

Saturday, 22 July 2023

Various types of electrical motors

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

Thursday, 20 July 2023

Major power system projects of India 2022

Some of the major electricity and power projects and systems in India in 2022:

- Solar projects: India is one of the leading countries in terms of solar power generation. In 2022, the country added over 10 GW of solar capacity, bringing the total installed capacity to over 45 GW. Some of the major solar projects in India in 2022 include the Bhadla Solar Park in Rajasthan, the Kurnool Ultra Mega Solar Park in Andhra Pradesh, and the Rewa Ultra Mega Solar Park in Madhya Pradesh.

- Wind projects: India is also a major player in the wind power sector. In 2022, the country added over 5 GW of wind capacity, bringing the total installed capacity to over 38 GW. Some of the major wind projects in India in 2022 include the Jaisalmer Wind Park in Rajasthan, the Kutch Wind Park in Gujarat, and the Mahanadi Wind Park in Odisha.

- Transmission projects: India is also investing heavily in transmission infrastructure. In 2022, the country added over 5,000 kilometers of transmission lines, bringing the total length of transmission lines to over 200,000 kilometers. Some of the major transmission projects in India in 2022 include the North-South Corridor, the East-West Corridor, and the Green Energy Corridor.

- Smart grid projects: India is also investing in smart grid technology. Smart grids are designed to improve the efficiency and reliability of the electricity grid. In 2022, the country launched a number of smart grid projects, including the Smart Grid National Mission and the Smart Grids for All scheme.

These are just a few of the major electricity and power projects and systems in India in 2022. The government is committed to increasing the share of renewable energy in the country's electricity mix and to improving the efficiency and reliability of the electricity grid. These projects will help India to achieve its energy goals and to provide reliable and affordable electricity to its citizens.

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

At SparkED, we strongly believe in supporting and promoting the work of young researchers and scientists. We are interested in featuring and showcasing the groundbreaking studies, experiments, and ideas of emerging talents who are pushing the boundaries of knowledge and innovation.

-

Transformers are rated in kVA (kilovolt-amperes) because they supply both active (real) and reactive power, and their losses dep...

-

Why Grounding Wires Are Not Insulated? Grounding wires, also known as earthing wires, are left uninsulated for safety reasons. Here are some...

-

In a three-phase system, the voltage between two phases is not simply the sum of the individual phase voltages (220V + 220V = 44...