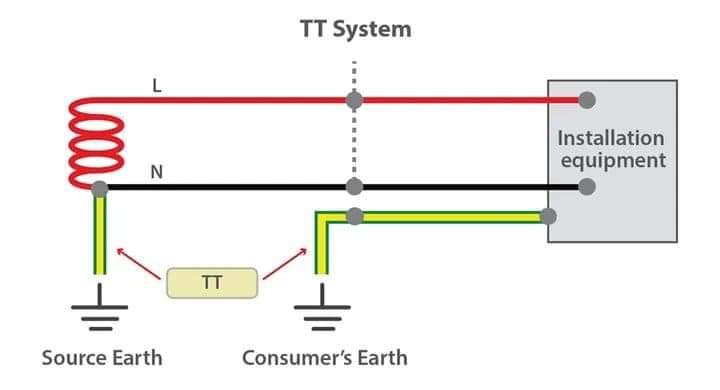

1. TT System: Imagine a scenario where each house or building has its own little earth rod, like planting a flag on the moon, but for electricity. Here, the "T" stands for "Terra" (Earth in French), and it's all about direct connection to earth. The power source (like a transformer) is connected to earth, and so is each consumer's installation, but separately. If there's a fault, the current has to travel through the earth to get back to the source, which might make Mother Earth grumble a bit with all that current. It's like each house has its own private line to the earth's core, which sounds cool but can be tricky for fault detection without an RCD (Residual Current Device).

2. IT System: Here's where things get a bit rebellious. The "I" stands for "Isolé" (Isolated), and the "T" for "Terra". In this system, the power source isn't directly connected to earth; it's isolated, like a lone astronaut in space. The consumer's equipment is earthed, but there's no direct path for fault current back to the source through the earth. This setup is like saying, "We'll deal with faults on our terms." It's often used in places where continuity of service is crucial, like hospitals, because you can keep running even with a first fault, but if a second fault occurs, you might have fireworks.

3. TNS System: Now, let's get organized. TNS stands for "Terra Neutral Separated". Here, the neutral and protective earth conductors are separate all the way from the source to the consumer. It's like having two different highways for your neutral and earth traffic, ensuring they don't mix. This system is like the Swiss Army Knife of grounding systems - versatile, efficient, and it keeps things very clear-cut. If there's a fault, the protective device knows exactly where to look because the earth path is distinct.

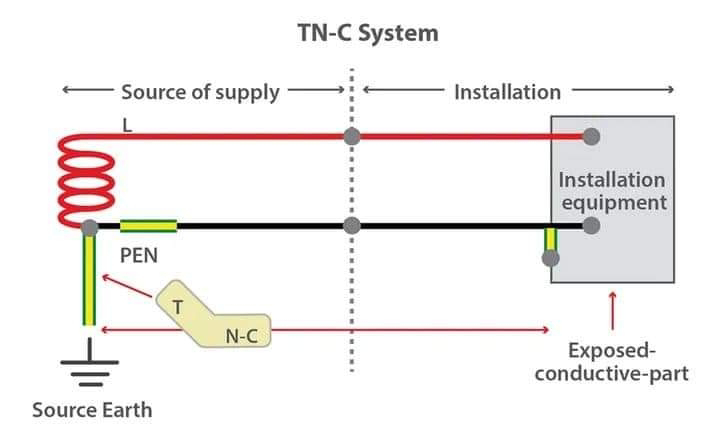

4. TNC System: This one's a bit of a mash-up. TNC stands for "Terra Neutral Combined". Here, the neutral and earth are the same conductor, known as the PEN (Protective Earth and Neutral) conductor. It's like a dual-use lane on a highway where both earth and neutral traffic share the road. This can be efficient but risky if there's a break in this conductor because then, all your earth points could rise to line voltage. It's like if your emergency exit also doubled as the main road, potentially leading to some very confused electrons.

Each of these systems has its quirks, advantages, and scenarios where they shine or where they might cause more headaches than solutions. Remember, in the grand scheme of electrical systems, these are the unsung heroes, keeping us safe from the whims of electricity, one wire at a time.